- Home

- Knowledge hub

Grow your revenue by predicting critical part breakdown

4 min. read

Shelly Boom

Breakdown of critical machine parts frequently leads to long downtime and often needs an experienced service engineer on-site for replacement. A predictive maintenance service to predict such failures before they occur will increase the machine’s availability and grade of your service contracts.

Many machines and lines have critical components with a long design lifetime, but often these parts will fail during the machine lifetime. Breakdown of those critical parts is devastating for the production process and costs your customers a lot, since most companies don’t have these critical parts in stock. These risks can be reduced with a predictive maintenance service for critical equipment where the condition is continuously monitored.

An industrial pump, critical machine part of production process

An industrial pump, critical machine part of production process

Although not seen as a standard wear and tear part, certain parts of a machine will eventually wear down at some point within the lifetime of the machine. These parts are often not standard components and are specifically made for a certain machine type or series. Therefore replacing requires special parts and skilled technicians.

As a result, these repairs are regularly of longer duration and can have significant impact on the production and reputation of both the machine builder’s brand and customer side. What if you could predict such failures based on data available on PLC level or if needed with additional sensors?

Experienced service engineers can often decide if the machine is running well by feeling the vibrations or just by listening to the machine to identify the cause. Machine builders can use their expertise and combine it with machine data to determine when parts are at the end of life by measuring symptoms to uncover the causes of faults. Data analysis of failed parts and parts close to end of life can be combined with data sciences leading to identifiable patterns.

Rotations, vibrations, ultrasonic sound, temperature and current or oil usage are potential indicators of wear and are relatively easy to monitor with sensors or PLC data. Monitoring the right data and comparing them with known patterns is the link bringing your combined service experience out on each machine 24/7/365.

A predictive maintenance strategy will lead to early warnings to prevent machine equipment failures

A predictive maintenance strategy will lead to early warnings to prevent machine equipment failures

Potentially, you and your customer know a failure is likely to happen prior to it happening. Replacing parts and doing the critical maintenance service before breakdown at a time where the impact on production is limited, can increase the grade and revenue of your service contracts and lead to savings for your customers due to reduced negative impact on their production which can be very significant. Questions like what a lost production hour costs, as well as impact in connection with a standstill over many days often will make such service contracts very attractive for your customers.

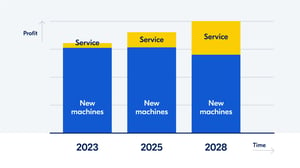

A critical monitoring system where you gather real-time data and set alarmings based on recognisable data patterns for machine parts with defined lifetime increases the machine’s uptime and customer loyalty. By offering an additional predictive monitoring service contract for a fee, you can go from unplanned to planned downtime when replacing parts. This is guaranteed to lead to new turnover.

Worn bearings within a pump may result in vibration, temperature change, displacement, down time or oil debris. Alert the customers that a failure is likely to happen prior to it happening and plan a replacement together with the customer. This way your customer can benefit from a service with a minimum of impact on production.

Effective monitoring uncovers the root cause, preventing recurrence and potentially solving other related faults as well. Together with the engineers and after sales specialists the critical parts are identified and tests are made on defective parts. Additionally, utilizing data science models are created to detect patterns in data, which can lead to a successful monitoring strategy.

Frequency sensor monitoring with thresholds for warnings and alarm condition

Frequency sensor monitoring with thresholds for warnings and alarm condition

Here is a simplified overview of how to expand your service model with preventive monitoring of critical equipment:

The first phase is to analyse the current failures of critical equipment. Determine which parts have a significant critical impact on the production process due to leadtime and need for skilled service technicians regarding a replacement. Then establish if any parts data, with a clear statistical correlation and causality between the given value and the condition of the part in question, is being captured.

Consider if such data are available on PLC level or can be captured from connected devices or an additional sensoric would be needed. Avoiding extra sensors would always be preferable, as they also have a certain failure rate. Considering current sensors on the machine and potentially using their capability to detect frequencies, temperature or acceleration via for example IO-Link can be an option.

A close cooperation between data scientist, after sales service and development engineers is needed to determine if patterns recognised are relevant or just 'white noise'. Based on the above, a project plan and test scheme is developed.

Carry out in-house tests on machines/sub assemblies of the critical components in question to strengthen or refute the hypothesis. Develop and refine your models.

Make a field test and based on data science from certain machines in the field equipped with the needed changes and gain field experience of effectiveness to ensure you are not overselling this service to your customer base and build confidence in the model and potential business model.

Define how this increased value is most efficiently utilised towards the customers to increase revenue, satisfaction and brand recognition:

Would you like to prevent critical failures and have more happy and profitable customers? By introducing preventive maintenance service for critical equipment, you will improve your customer relationships and increase customer loyalty.

If you need help on defining your digital strategy and making value out of data science, feel free to consult one of our industry experts without any obligations. Or get some inspiration from our E-book: Service opportunities for OEMs to boost revenue and meet customer demands including use cases and new revenue examples.